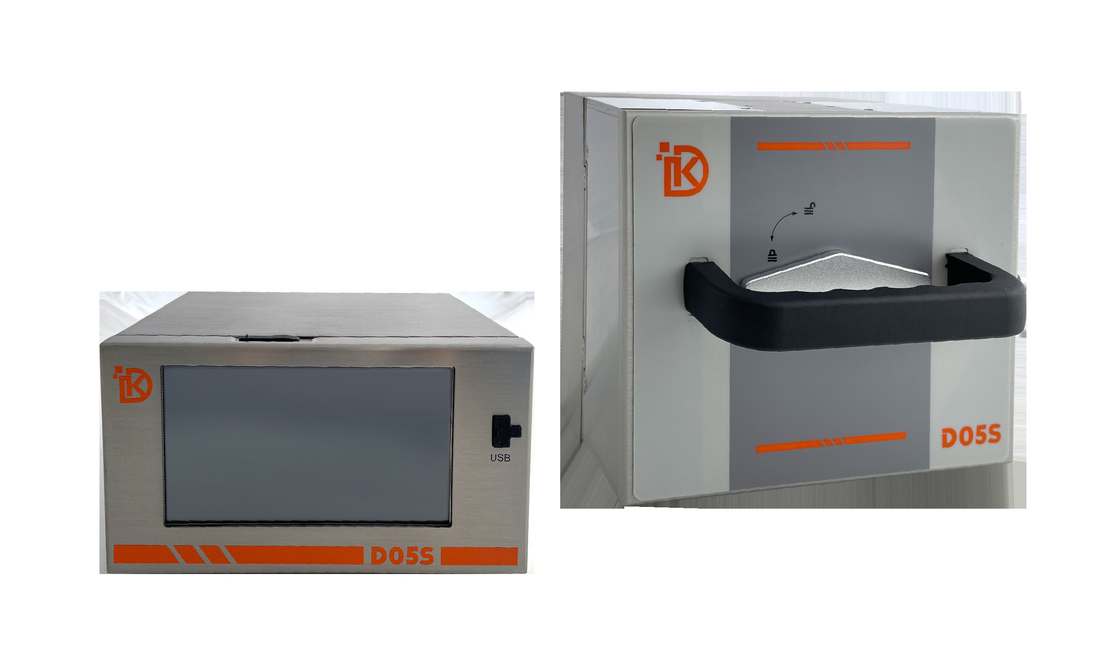

D05S Near Edge TTO Coding Machine With 53mm Print Head

DIKAI D05S Qr Code Printing Machine Thermal Transfer Overprinter (TTO)

-

Technical Details:

| Specification |

| Print Head |

Kyocera, 53mm; 300DPI |

| Print Area |

Intermittent: 53mm*70mm

Continuous: 53mm*150mm

|

| Ribbon Size |

55mm*600m |

| Printing Frequency |

Intermittent: up tp 350PPM

Continuous: up to 40 meters/ minute

|

| Environmental Operation Temperature |

0-40℃ |

| Relative Humidity |

10%~95% (non-condensing) |

| Power |

AC110~220V, 50/60Hz, 150W |

| Air Supply |

6bar/ 90PSI(MAX) dry uncontaminated |

| Weight |

Print head: 8.5kg, Control box: 2.0kg |

| Dimension(L*W*H) |

Print Unit: 210mm*210mm*185mm

Controller Box: 233mm*180mm*128mm

|

What is TTO Printing?

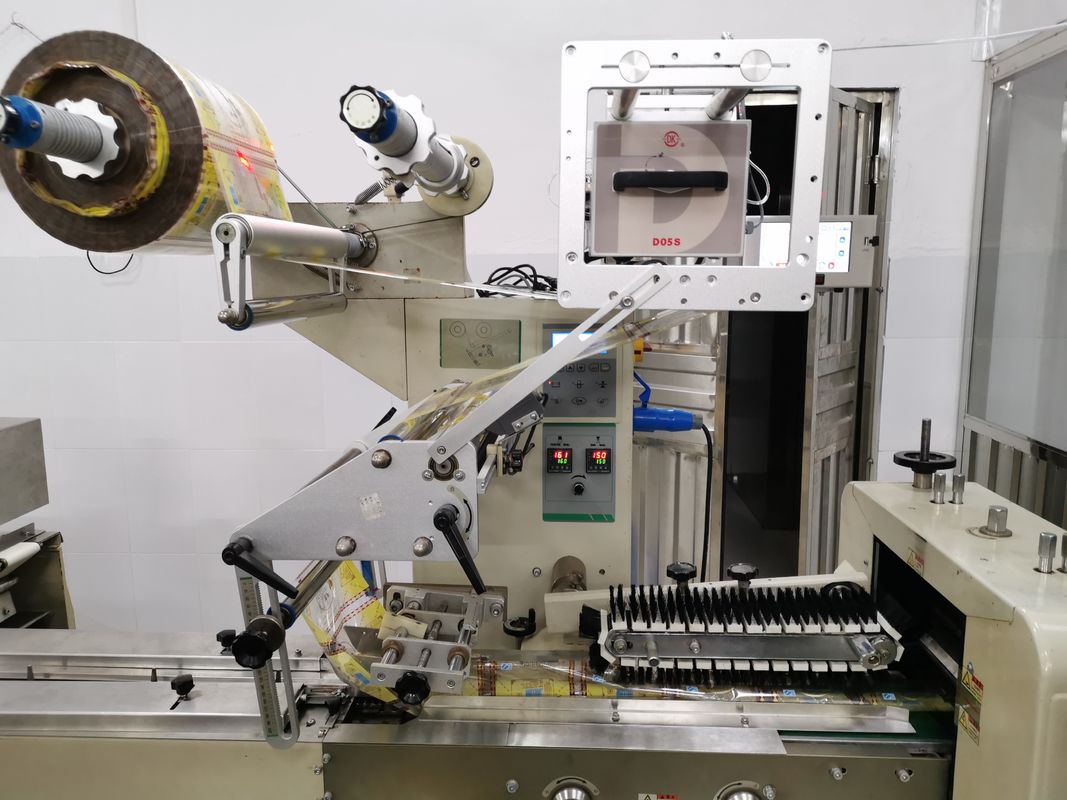

TTO stands for Thermal Transfer Overprinter. TTO Printer is an ideal printing product for most flexible film packaging applications. The printing process produces a very high-resolution code onto the package that is easy to read and ensures no degradation of the aesthetic quality of the packaging film artwork and design.

Heat transfer printing gives heating to nozzles and ribbons. The nozzle consists of a ceramic-glass assembly with 12 heating spray printing points per millimeter. It can provide printing quality up to 300 dpi resolution. The printing information is prepared in a heating nozzle, and individual printing points also need to be heated. Color pigments on aluminum foil are heated and printed on the required areas.

What are the benefits of thermal transfer overprinter technology?

1. 300 dpi resolution.

Heat transfer printing gives heating to nozzles and ribbons. The nozzle consists of a ceramic-glass assembly with 12 heating spray printing points per millimeter. It can provide printing quality up to 300 dpi resolution. The printing information is prepared in a heating nozzle, and individual printing points also need to be heated. Color pigments on aluminum foil are heated and printed on the required areas.

2. The operation cost is economical, and various information can be printed.

Intelligent thermal transfer printer (TTO) can freely program and generate various data for each identification job. High-resolution nozzles can print characters, graphics, batch numbers, real-time dates and bar codes. With the mature thermal transfer coding technology, the packaging materials can be coded directly. Therefore, labels are no longer needed, and the cost is also significantly reduced.

3. Provide the most economical solution for the packaging industry.

The most advanced thermal transfer coding technology is adopted, and the consumption of ribbon is extremely small, which makes the thermal transfer coding machine have great economic advantages in the flexible packaging industry. This equipment can be used to mark small packaging bags, outer metal foils, packaging films, continuous films, etc., and can also be used to mark filling and sealing machines.

4. Intermittent printing.

It is used for intermittent printing of intermittently operated (stationary/start-up) production lines, that is, printing jobs are completed during the stationary period. The real-time printing program is started according to the signal sent by the thermal transfer printer, and the printing head moves downwards and integrates with the supporting plate to move on the printing surface. After printing, the product moves forward and the print head returns to the initial position.

5. Continuous printing.

Continuous printing is used in the continuous production line, and thermal transfer coding is carried out on moving products. The packaging machine sends a signal (for example, asking for printing marks), and the print head is pushed into the roller on the bracket to start printing. As soon as the print job is finished, the print head immediately returns to the initial position. The printing speed is automatically adjusted to ensure stable and clear printed images.

Benefits

Thermal transfer overprinters use a high-resolution thermal printhead, which melts a wax and/or resin-based ink from a very thin thermal transfer ribbon coating onto the surface of your product.

-

-

● Optimizing your benefits:

-

Can print real-time date, time and batch No.; can edit print text as you want; super 650-meter ribbon reducing the frequency of changing, saving your production time; user friendly interface making it easy to operate; easy-to-learn editing software. Optimizing your Production line and reducing the cost.

-

● High Quality Print:

-

High-Resistance Codes: Thermal transfer overprinter can be used in flexible packaging printing creates a highly resistant product that is able to withstand any chemicals, humidity, UV rays, abrasion and climatic changes that your packaging may encounter on its journey through the supply chain.

-

Working principle of thermal transfer printer: each print head has a row of heating elements; These components take glaze (a kind of vitreous thin layer) as a protective layer, and are driven and heated at appropriate time. The heat generated by these elements melts the ink on the ribbon and transfers the ink to the substrate due to the pressure of air pressure. Only the characters of the thermal transfer printer are not typed independently and can be printed. The fastest coder in the world can be 600MM per second.

-

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!