Intermittent Continuous TTO Coder/TTO Printer

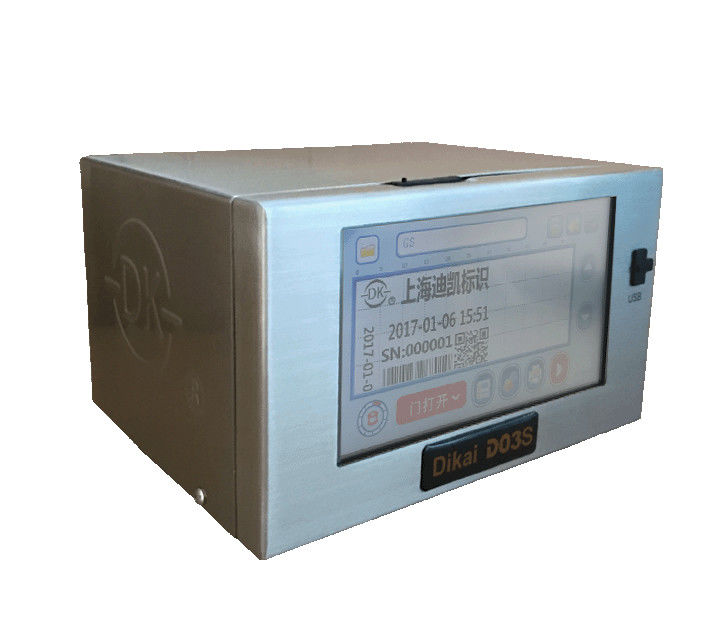

DIKAI D03S Thermal Transfer Overprinter (TTO)

Compared to traditional contact coders such as hot-stamp or roller coders, thermal transfer overprinting offers superior print quality and lower costs.

From label overprinting, to high speed digital coding on vertical bagging machines with flexible packaging, the Dikai thermal transfer printer is able to deliver fast print speeds, minimising downtime and ensuring the lowest possible cost of ownership.

-

The thermal transfer printer, also known as TTO printer, is an intelligent product of the printer, which can replace the originally used ribbon printer, without replacing the nails. The printing head adopts Japanese crystal porcelain high-quality printing head, which can easily change the contents to be printed by computer, such as production date, product batch number, validity period, time, shift and other variables. TTO intelligent coding machine can cooperate with various packaging machines, such as particle packaging machine and pillow packaging machine, etc. It is as convenient as the original ribbon coding machine in printing date and other contents in cooperation with the packaging machine, and at the same time, it is as convenient to change the printed contents as the inkjet printer. It can also print more characters, numbers and patterns with high quality on flexible packaging films, aluminum-plastic composite films and labels.

TTO coding machine is specially developed for emerging markets and is easy to use.

Simple, real-time automatic digital coding solution, intelligent operation.

TTO coding machine can improve efficiency and quality, and is easy to use and traceable.

Good printing quality enhances the image of the company and products, especially for high-end packaging products.

Realize network control and image design through computer or operating keyboard.

Economical solution for packaging industry.

The thermal transfer printer (TTO) can be easily programmed, enabling operators to quickly change messages. This reduces the downtime and energy consumed by replacing molds and rollers when using hot stamping and roller printing equipment. Advanced TTO uses bidirectional ribbon drive to accurately control ribbon tension. When TTO is used, unreliable mechanical solutions, such as elastic adjusting arms, are not needed, and meanwhile, ribbon saving is realized by precisely controlling the position of ribbon.

Real-time printing of variable data.

TTO is a digital jet printing solution, which means that it has both real-time clock function and I/O communication function. In addition to jet printing static codes, advanced TTO can also jet print unique data on each package. TTO can spray print enhanced traceability information such as packaging timestamp, or higher-level coding such as unique serial number and related bar code, depending on production requirements.

Technical Details:

| Specification |

| Print Head |

Kyocera, 32mm; 300DPI |

| Print Area |

Intermittent: 32mm*60mm

Continuous: 32mm*100mm

|

| Ribbon Size |

33mm*500mI |

| Printing Frequency |

Intermittent: up tp 350PPM

Continuous: up to 40 meters/ minute

|

| Environmental Operation Temperature |

0-40℃ |

| Relative Humidity |

10%~95% (non-condensing) |

| Power |

AC110~220V, 50/60Hz, 150W |

| Air Supply |

6bar/ 90PSI(MAX) dry uncontaminated |

| Weight |

Print head: 8.5kg, Control box: 2.0kg |

| Dimension(L*W*H) |

Print Unit: 188mm*190mm*180mm

Controller Box: 210mm*180mm*155mm

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!